Our Know-How

DTEC is motivated by state-of-the-art technology to design and produce high-performance inspecting and monitoring solutions for railway operation and maintenance. We are specialized in various NDT techniques including ultrasonic testing, and apply 2D and 3D machine vision, artificial intelligence (AI), and data mining.

1 Ultrasonic Testing

Ultrasonic testing (UT) is one of the classic non-destructive testing techniques based on the propagation of ultrasonic waves in the object to be inspected. DTEC applies conventional UT and advanced UT technology for railway wheels, axles, and rail inspection.

2 Machine Vision

Machine Vision technology is a high-value method that DTEC employs to perform precise measurement and fast detection on profile and surface condition monitoring. Thanks to the contribution of Artificial Intelligence know-how, our smart monitoring and measurement solutions are highly qualified for classified fault alarming and life time predicting.

2D IMAGE PROCESSING

We are major players in the field of machine vision inspection for more than two decades, starting from traditional 2D image processing for rail vehicle wheels, brakes, and pantograph strip measurement in motion. Continuously, we update our imaging technology with neural network methods and then artificial intelligence that makes our machine vision systems smarter in detecting and analyzing of fault conditions, as well as life cycle prediction for plenty of railway-related components.

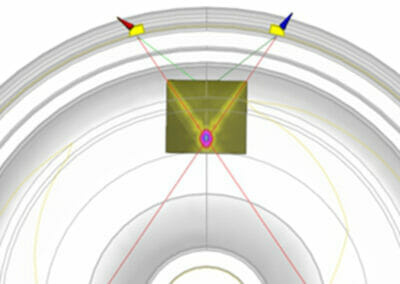

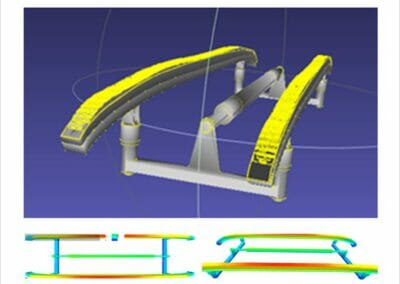

3D RECONSTRUCTION

3D imaging gives us an interactive view of a monitored target. Together with reverse engineering technology, using 3D data allows to quantify the material loss due to friction at wheel tread, pantograph carbon strip, and brakes. Similarly, it can be used to detect tiny movement or displacement of vehicle key parts like loose bolts, deformed parts, etc. Besides, it also helps to suppress false alarms in 2D inspection caused by water, mud, and displacement within the tolerance limit.

3 Artificial Intelligence

It has been years that Artificial Intelligence (AI) became a strategic and continuously developed technology platform that makes traditional image-based inspection smarter in terms of failure recognition and also represents a powerful tool for data mining in Prognostics and Health Management (PHM).