Company Profile

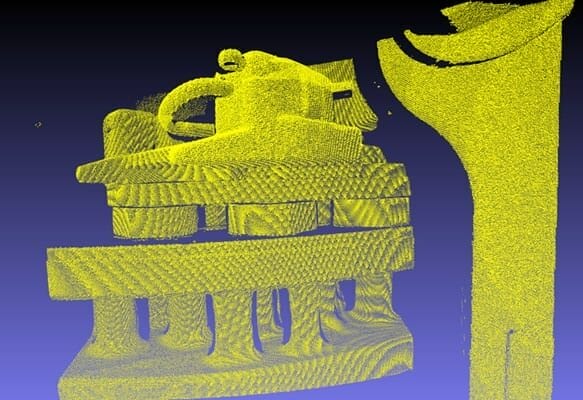

DTEC GmbH is an international system integrator providing customized inspection solutions for railway. Focusing on the application of mature and advanced technology to the railway industry, DTEC GmbH offers turnkey solutions to customers worldwide with specialized teams in railway marketing, R&D, Production and engineering.

In Germany, we own labs, workshops and test facilities for product development and production. Together with our long-term partners in research, development and marketing, we combine advanced technology with rich railway experience to strongly support our customers.

Our Know-How

LATEST NEWS & EVENTS

RailLive2025 in Madrid

26-28.November.2025

We’re excited for Rail Live 2025 in Madrid! DTEC GmbH will be there from 26–28 Nov.2025, connecting with industry peers and showcasing our latest innovations.

Trako 2025 in Poland

23-26.September.2025

We’re looking forward to connect, exchange ideas, and have great conversations about the future of rail. See you in Gdańsk!

IoT AI & DATA in Rail, Köln

20-21. May 2026

Köln, Deutschland

Save the date and looking forward to see you in Köln!